At Playrite, every sports surface we create reflects our unwavering commitment to quality, durability, and safety.

We bring together expert craftsmanship and cutting-edge technology to ensure every product meets the highest standards.

From start to finish, our manufacturing process is guided by rigorous quality controls, resulting in premium artificial sports surfaces trusted by clients around the world.

Here’s a closer look at how we manufacture our surfaces, from raw materials to final delivery:

Every Playrite surface begins its journey with the careful selection of high-quality raw materials.

By choosing only materials that meet our strict standards for performance and safety, we lay the foundation for the long-lasting, reliable surfaces our customers depend on.

This attention to detail from the very start is what sets Playrite products apart.

We manufacture different types of surfaces tailored to diverse sporting needs:

Needlepunch Surfaces:

Constructed from layered, needled fibres, needlepunch surfaces offer a durable and versatile solution for multi-sports pitches.

With minimal sand content, they help reduce maintenance demands and costs. The absence of secondary backing not only simplifies installation but also enhances porosity, allowing for faster, more efficient drainage, ideal for year-round playability.

Tufted Surfaces:

Tufted surfaces are created by punching fibres through a primary backing to form U-shaped tufts, closely mimicking the look and feel of natural grass.

This construction delivers excellent performance, making it an ideal choice for sports where a realistic turf experience is essential, such as football, rugby, and general training areas.

Woven Surfaces:

At Playrite, our woven surfaces are created by interlacing the backing yarn and pile yarn, resulting in a dense and highly stable pile.

This construction provides a consistent ball roll, exceptional durability, and non-directional strength, making it the ideal choice for high-performance sports applications where reliability and precision matter most.

Our manufacturing process combines traditional craftsmanship with state-of-the-art machinery.

Using advanced cutting, shaping, and assembly tools, our skilled technicians build each surface with precision and care.

As a result, every product meets Playrite’s exacting standards and delivers consistent, high-level performanc, time after time.

At Playrite, quality and safety are at the core of everything we do.

Before any surface leaves our facility, it goes through rigorous testing and inspection, all aligned with internationally recognised standards, including ISO 9001 for quality management and ISO 14001 for environmental responsibility.

Our dedicated quality control team assesses every inch of the surface for:

Beyond ISO certifications, our products meet multiple industry standards:

Playrite takes pride in its efficient and reliable shipping network across the UK and internationally. Our surfaces reach customers through a dedicated network of distributors, ensuring timely delivery whether by plane, truck, or ship.

From local schools and amateur sports clubs to professional athletes worldwide, Playrite surfaces enable communities everywhere to enjoy high-performance, durable, and safe sports environments.

Ready to elevate your sports facility with premium artificial surfaces? Contact Playrite today to learn more about our products and manufacturing excellence.

Clubs, schools, and UEFA-approved stadiums across the UK use 3G football pitches more than any other artificial playing surface. As a result, they have made 3G pitches the gold standard by offering an all-weather, high-performance alternative to natural grass.

Recognising their impact, Sport England endorses 3G turf as:

“Durable, safe, year-round playing surfaces, able to withstand intensive use and all kinds of weather.”

So, what is a 3G football pitch, and why has it become the preferred choice for football at every level?

The term ‘3G pitch’ stands for third-generation artificial turf. It refers to the latest evolution in synthetics surfaces, specifically designed for football and rugby.

Unlike older synthetic pitches (like traditional AstroTurf), engineers design 3G artificial turf to replicate the natural feel and performance of real grass. Additionally, the turf manufacturers use tufted synthetic fibres filled with a combination of sand and rubber granules to provide players with better grip, ball control, and cushioning.

So, how is a 3G football pitch constructed?

A 3G surface is built using:

The rubber infill plays a vital role:

This construction helps reduce abrasiveness and supports playability across all weather conditions.

Modern 3G artificial turf offers several significant advantages over natural grass and older turf systems:

Whether you’re a school, sports facility, or grassroots team, a 3G football pitch offers consistency and reliability.

Key reasons why clubs across the UK choose 3G:

At Playrite, our Conqueror range includes three 3G artificial turf systems.

Each option has a different pile height to suit various levels of sport and intensity of use:

Each pitch is built to meet FIFA Basic performance standards and ensure long-lasting quality.

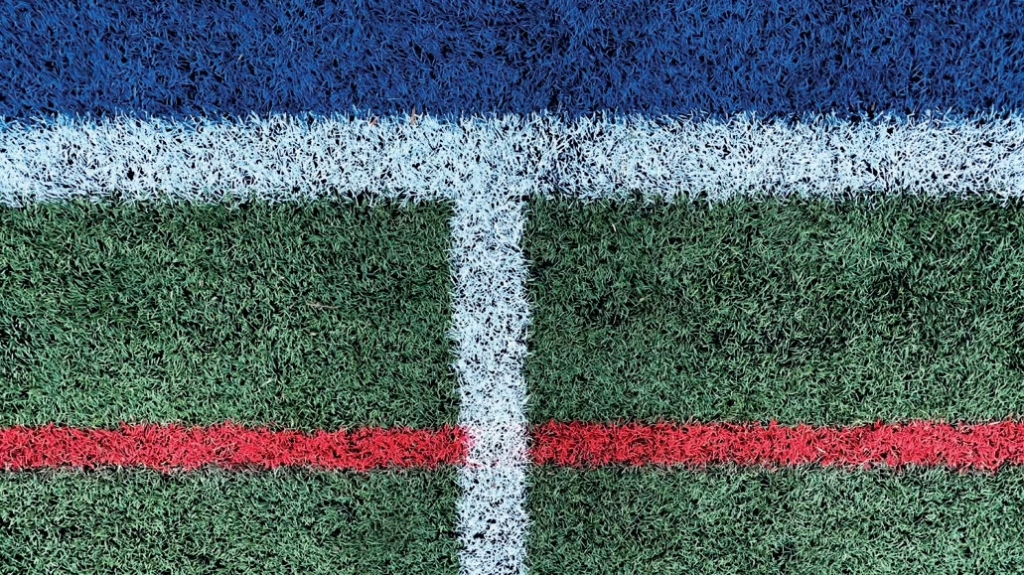

Spread across 27 acres in central London, Paddington Recreation Ground needed a durable, professional-quality artificial football pitch to support high levels of community use. Following consultation with ETC Sport Surfaces, Playrite’s Conqueror 60 was selected for its performance and reliability, featuring a green playing area with a blue border to reflect the site’s branding.

Want more detail? View the full case study on Paddington Recreation Ground

Whether you’re upgrading school grounds, building a new football complex, or renovating a community sports hub, a 3G pitch is a future-proof investment.

Click here to discover our full range of football pitch surfaces.

Ready to discuss your project?

Call us on 01924 412488 or email info@playrite.co.uk. Our team will help you select the most suitable surface based on your project’s specific needs.

Manufacturers design a 3G football pitch as a third-generation artificial turf that closely mimics natural grass. To achieve this, they use synthetic fibres with sand and rubber infill to provide a safe, durable, and high-performance playing surface.

Rubber infill fills a 3G pitch, and FIFA and the FA officially approve it. Manufacturers mostly use “4G pitch” as a marketing term since no official standard exists yet.

Although we back our 3G pitches with a minimum 5-year warranty, regular maintenance allows them to perform at a high level well beyond that period, making them a smart, long-lasting investment.

At Playrite, we design 3G turf systems to drain freely and perform in all weather. However, poor maintenance can cause drainage issues over time. When compaction or contamination affects the infill (sand and rubber), the surface loses porosity and starts retaining water. Therefore, groundskeepers prevent this by performing regular upkeep, keeping the pitch safe and high-performing.

To keep your 3G pitch in top condition, regularly drag brush the surface to prevent infill compaction. In addition, remove debris to avoid contamination and inspect the drainage system to ensure proper performance. Occasional deep cleaning and infill top-ups may also be necessary to maintain optimal playability.

Greenwood Park Lawn Tennis Club (LTC), based in Chiswell Green, continues to enhance its offering to the local community with the successful completion of a significant tennis court resurfacing project. St Alban’s community recognises Greenwood Park LTC for its inclusive ethos and wide-ranging tennis programmes. These range from mini tennis for young children to competitive Herts County League fixtures. The club welcomes players of all ages and skill levels.

Recently, Greenwood Park LTC officially opened launched newly resurfaced tennis courts. The club completed the project in collaboration with ETC Sports Surfaces, using Playrite’s Matchplay 2 XL surface. A well-attended Grand Opening event marked the occasion and underscored the club’s commitment to providing high-quality, accessible facilities for both its members and the wider community.

Before the resurfacing, the courts showed visible signs of wear. Surface inconsistencies and reduced grip were negatively affecting both play quality and user satisfaction. Therefore, the club recognised the need for a long-term solution that could withstand heavy use and varying weather conditions. They sought a surface that combined performance, durability, and low maintenance.

Playrite’s Matchplay 2, part of their advanced needle-punch range, was chosen for its proven success at club level. Specifically, this surface is designed for high-performance play. It offers exceptional durability and a unique dimpled texture that improves grip and ball control. Additionally, with a medium ITF pace rating (3) and excellent porosity, it delivers consistent ball bounce and reliable play all year round. Therefore, these qualities make it perfect for busy community clubs with diverse players.

The new courts offer a resilient, low-maintenance surface, making them perfect for both recreational and competitive tennis. During the Grand Opening, the club showcased its inclusive vision by engaging local schools, community groups, and neighbouring clubs. As a result, over 100 attendees joined the celebration, including St Albans’ Mayor Jamie Day and former Mayor and High Sheriff Annie Brewster, who performed the ceremonial ribbon cutting.

During the event, attendees participated in a range of tennis activities for all ages. From toddlers as young as three to seasoned adult players, the coaching team ensured that everyone had the opportunity to try the new surface. Rackets were available to borrow, so even beginners felt welcome.

The tennis court resurfacing project has improved the club’s facilities. It has also strengthened community engagement and encouraged greater participation in tennis. Matchplay 2, made in the UK by Playrite, uses UV-stable fibres and a design that drains faster than traditional tufted surfaces. It comes with at least a five-year warranty, making it a reliable and lasting choice for clubs that want quality and durability.

Greenwood Park LTC’s latest upgrade shows the value of using high-performance, all-season surfaces. This is part of a bigger effort to encourage healthy, active living and make sports more accessible. The new courts are an important step forward for the club and the whole St Albans community.

To learn more about Matchplay 2 or explore surface options for your facility, contact Playrite’s surface specialists today.