Learn how Playrite expertly manufactures premium sports surfaces in the UK, using precision engineering, top-quality materials, and rigorous standards

At Playrite, every sports surface we create reflects our unwavering commitment to quality, durability, and safety.

We bring together expert craftsmanship and cutting-edge technology to ensure every product meets the highest standards.

From start to finish, our manufacturing process is guided by rigorous quality controls, resulting in premium artificial sports surfaces trusted by clients around the world.

Here’s a closer look at how we manufacture our surfaces, from raw materials to final delivery:

Every Playrite surface begins its journey with the careful selection of high-quality raw materials.

By choosing only materials that meet our strict standards for performance and safety, we lay the foundation for the long-lasting, reliable surfaces our customers depend on.

This attention to detail from the very start is what sets Playrite products apart.

We manufacture different types of surfaces tailored to diverse sporting needs:

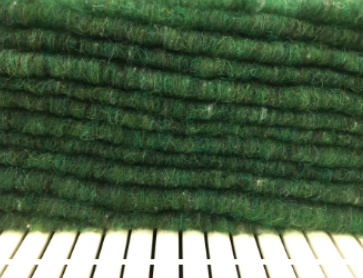

Needlepunch Surfaces:

Constructed from layered, needled fibres, needlepunch surfaces offer a durable and versatile solution for multi-sports pitches.

With minimal sand content, they help reduce maintenance demands and costs. The absence of secondary backing not only simplifies installation but also enhances porosity, allowing for faster, more efficient drainage, ideal for year-round playability.

Tufted Surfaces:

Tufted surfaces are created by punching fibres through a primary backing to form U-shaped tufts, closely mimicking the look and feel of natural grass.

This construction delivers excellent performance, making it an ideal choice for sports where a realistic turf experience is essential, such as football, rugby, and general training areas.

Woven Surfaces:

At Playrite, our woven surfaces are created by interlacing the backing yarn and pile yarn, resulting in a dense and highly stable pile.

This construction provides a consistent ball roll, exceptional durability, and non-directional strength, making it the ideal choice for high-performance sports applications where reliability and precision matter most.

Our manufacturing process combines traditional craftsmanship with state-of-the-art machinery.

Using advanced cutting, shaping, and assembly tools, our skilled technicians build each surface with precision and care.

As a result, every product meets Playrite’s exacting standards and delivers consistent, high-level performanc, time after time.

At Playrite, quality and safety are at the core of everything we do.

Before any surface leaves our facility, it goes through rigorous testing and inspection, all aligned with internationally recognised standards, including ISO 9001 for quality management and ISO 14001 for environmental responsibility.

Our dedicated quality control team assesses every inch of the surface for:

Beyond ISO certifications, our products meet multiple industry standards:

Playrite takes pride in its efficient and reliable shipping network across the UK and internationally. Our surfaces reach customers through a dedicated network of distributors, ensuring timely delivery whether by plane, truck, or ship.

From local schools and amateur sports clubs to professional athletes worldwide, Playrite surfaces enable communities everywhere to enjoy high-performance, durable, and safe sports environments.

Ready to elevate your sports facility with premium artificial surfaces? Contact Playrite today to learn more about our products and manufacturing excellence.